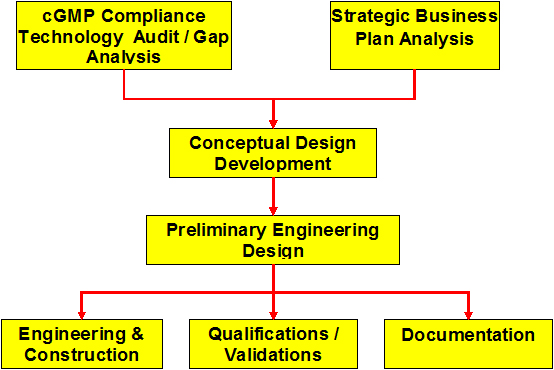

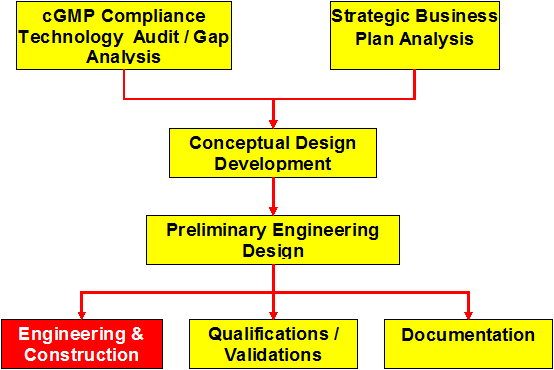

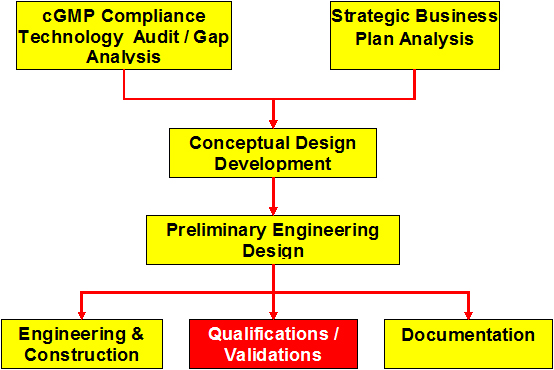

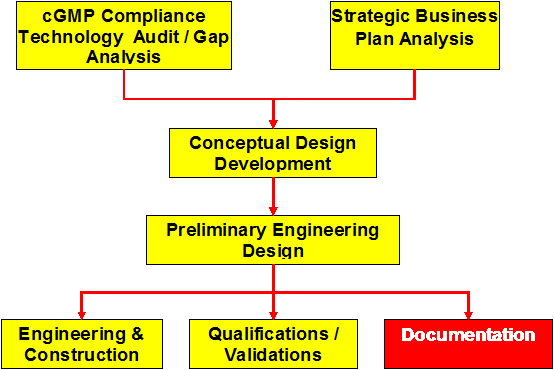

cGMP Compliance Technology Audit/Gap Analysis

- Equipment and Facilities

- Processes

- Quality Systems

- Documentation

- Organizational Structure

- Risk assessment

- Enable companies to determine which qualification/validation/facilities & equipment upgrades are necessary

- Provide support with the implementation of identified measures.

Development of the Conceptual Design

- Prerequisite and a guide to prepare technical requirements document (User Requirements Specifications) for economical and functional preparation and implementation of detailed engineering design project for facility and equipment upgrade/retrofit/new construction within the cGMP framework, based on the regulatory Risk assessment and strategic business development plan or analysis

Preliminary Engineering Design

- Field survey to confirm the layout of architectural system components and mechanical, electrical and plumbing infrastructure.

- Preparation of material, personnel and equipment flow diagrams for all process areas.

- Selection and defining utility requirements and Client`s needs associated with new and existing processes and equipment. Preparation of the process equipment list for Client`s review and approval that will form the basis for budgetary equipment costs. Organization (optional) of pre-selection of vendors and a bid process for the equipment to include US, European, Asian and local suppliers.

- Preparation of Area Classification and Pressurization Plan drawings for each of the processing areas with reference to European Grade levels as appropriate.

- Preparation room air change rate calculations and development of preliminary HVAC Zoning plans so that the assessments of existing and sizing of new HVAC equipment can be made.

- Recommendation of the affecting set points for room temperature, humidity and pressurization, as well as acceptable operating, alert and action limits and how these will be monitored and controlled.

- Preparation of a Validation Master Plan.

Engineering & Construction

- Field Project Management

- Design (Architectural, Civil, Structural, Mechanical, HVAC, Plumbing, Electrical, Process)

- Purchasing/Expediting

- Construction

- Validation

- Start-up / Commissioning

- Manufacturing/Processing Personnel Training

Qualifications/Validations

- Qualifications/Validations

- Basic concepts

- Master plans (a company specific qualification/validation concept)

- Project specific master plan (GMP, Validation, SOPís)†

- Qualification (DQ/IQ/OQ/PQ)

- Development and preparation of all qualification protocols and relevant SOPís

- Execution of the protocols (at customer request) or helping a customer to execute

- Preparation of GMP compliant documentation describing the qualification activities for the customerís facility

- Validation

- Full technical and manpower support for preparation of protocols and reports and execution activities (although the latter is typically done by the manufacturer).

- Scope Ė process, cleaning, analytical methods, computerized systems

- Preparation of all necessary validation SOPís carefully adapted to the customerís needs

Documentation

- Documentation

- Technical support and execution (per customer`s request) of all necessary documentation

- Scope - documentation concepts, SOP`s, production documentation (batch records, cleaning records, etc.), technical documentation (development reports)

- Documentation review

- Training

- Preparation for inspection

- Technical support and/or execution and follow-up services

- Scope - Self audits, Audits of suppliers, Customer audits, Regulatory audits

- Remediation (FDA 483`s, Warning Letters)

- Technical support in preparation or execution of responses to local and/or international regulatory agencies (for example, EIR, 483`s and Warning letters)

- Technical support in preparation and/or execution of the corrective and preventative action (CAPA) master plans

- Regulatory Submissions

- Technical support and/or execution and follow-up services

- Scope - DMF, COS, Comparability protocols, CMC section

- Training

- Design of the comprehensive training program to cover initial and ongoing training requirements

- Conducting general GMP and specific training sessions on continues basis